Search

Company locations

The whole picture – with just a single click. Find out here where our branches are located, what services they offer and how to contact them.

REMONDIS Group locations

Discover the world of REMONDIS with its approx. 900 branches and associated companies in over 30 countries across Europe, Africa, Asia and Australia.

Sophisticated mineral materials recycling

Over decades, processing technology for the production of recycled aggregates has been continuously improved; because only the best quality recycling materials can compete in the market, both in terms of construction technology and environmental protection. However, the most important production criterion for recycled aggregates remains the quality of input materials, i.e. the construction and demolition waste. In many applications, REMEXIT, with its outstanding properties, is now the best alternative to natural resources.

Origin, production and use of recycled aggregates

The process begins at the construction site with an appropriate disposal concept and the exploration and exclusion of possible contaminated components and corresponding controlled demolition. When we accept construction and demolition waste (CDM waste) including road rubble and asphalt, we check to what extent this mineral waste may be contaminated. By storing certain materials and qualities separately, we can ensure a consistently good, industrially manufactured recycling material.

Treatment of CDM waste

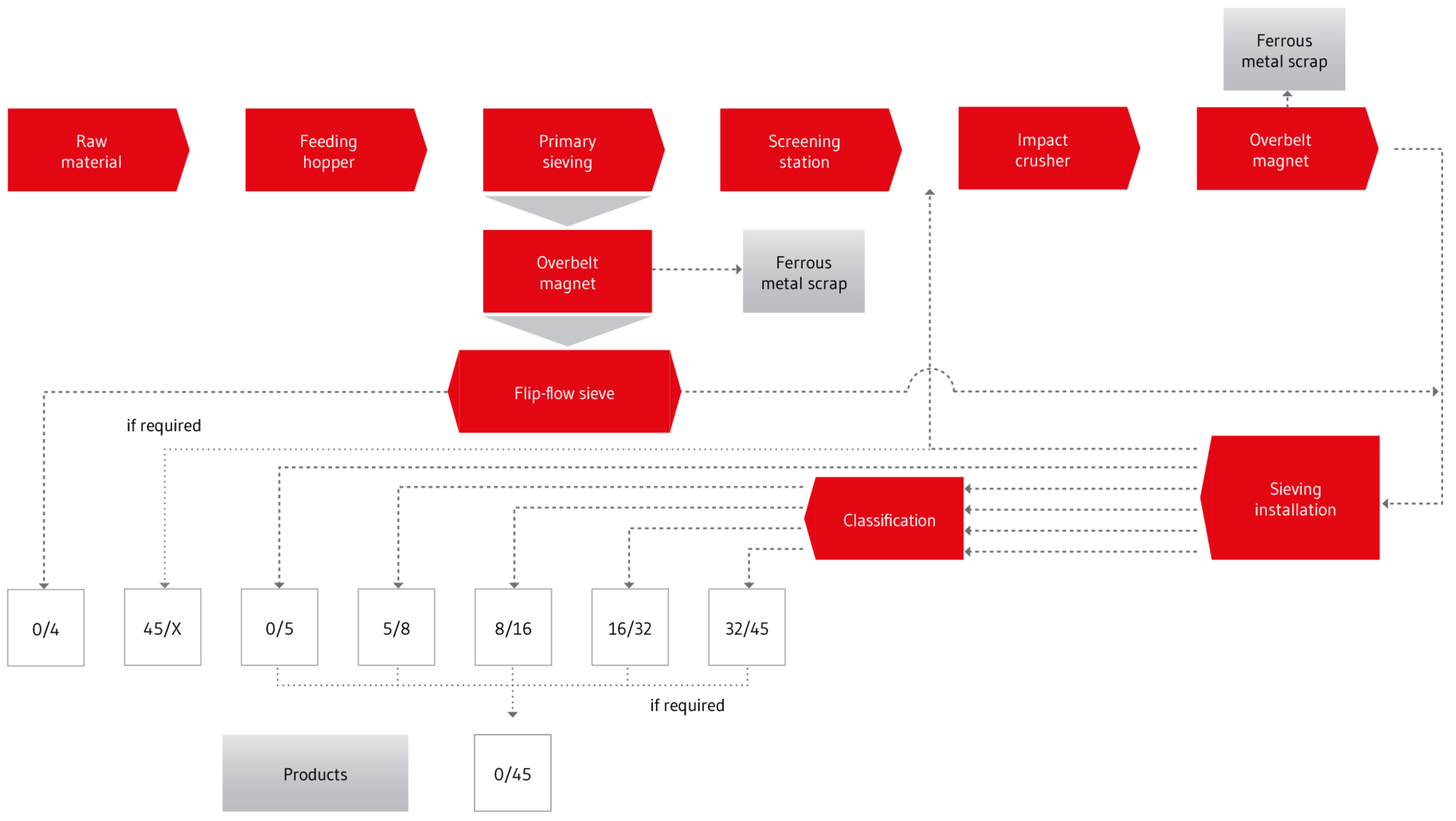

REMEXIT is produced by mechanical treatment of construction and demolition rubble in one of our numerous recycling plants. The resulting recycling materials thus fall under the term of industrially manufactured substitute construction materials. Processing generally comprises the steps of crushing, screening, sorting out impurities and separating metals, in this case iron, using magnetic separators. In order to achieve good recycling qualities from the CDM waste, individual steps are carried out several times on different grain sizes. The metals recovered during the process (e.g. reinforcing steel) are recycled.

The mineral fraction is classified and combined into different sieve lines depending on the intended use. In road construction, aggregates 0/32 and 0/45 are mainly used as a substitute for base layers.

The construction waste can also be processed on site by means of a mobile plant, enabling local recycling. However, most of the CDM waste is processed in our high-performance stationary recycling plants and subsequently marketed as REMEXIT recycled aggregate.